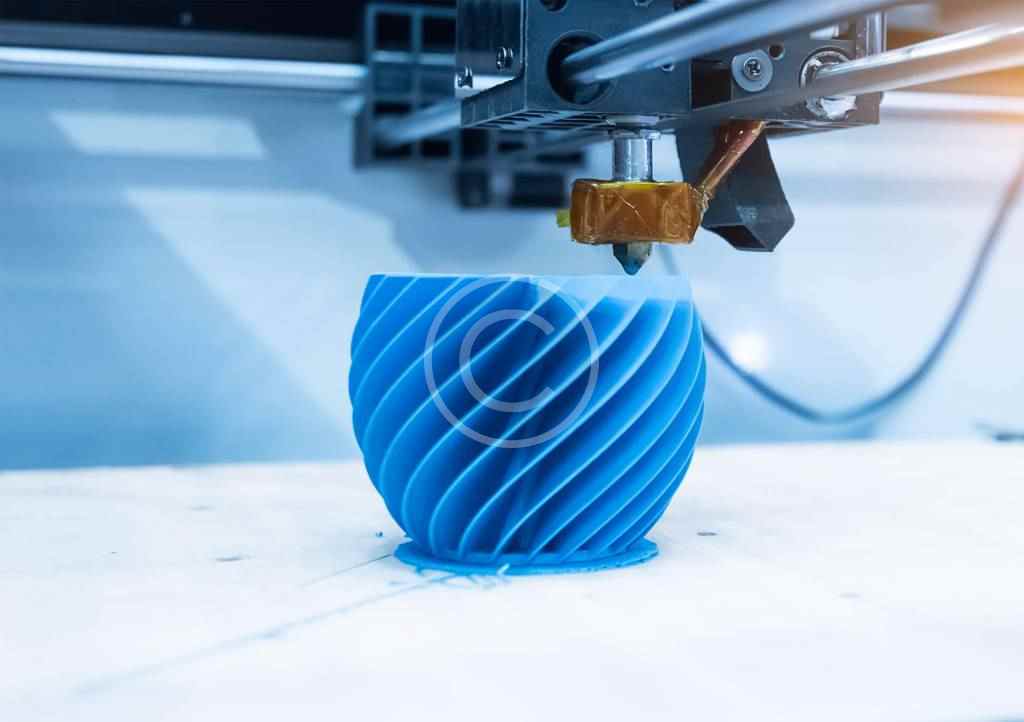

3D printing, or additive manufacturing, has emerged as a transformative technology with significant implications for sustainability in manufacturing and production. By building objects layer by layer from digital models, 3D printing offers several environmental benefits compared to traditional manufacturing methods.

How its applied

Reduction of Material Waste

Traditional subtractive manufacturing involves carving out parts from larger blocks of material, often resulting in substantial waste. In contrast, 3D printing uses only the material necessary to create the object, significantly minimizing waste. Some estimates suggest that 3D printing can reduce material waste by up to 90%.

Energy Efficiency

3D printing can be more energy-efficient than conventional manufacturing processes. By producing items on-demand and locally, it reduces the energy consumption associated with mass production and transportation. Additionally, the precision of 3D printing allows for the creation of lightweight structures, particularly beneficial in industries like aerospace and automotive, where reducing weight can lead to significant energy savings during the product’s use phase.

Recycling and Use of Sustainable Materials

Advancements in 3D printing have enabled the use of recycled materials, contributing to a circular economy. For instance, certain 3D printers can utilize recycled plastics or metals, reducing the demand for virgin materials. Innovative processes like EcoPrinting use waste polymers as source material, boasting a near-zero carbon footprint.

Localized and On-Demand Production

3D printing facilitates localized manufacturing, allowing products to be produced near the point of consumption. This localization reduces the carbon footprint associated with transportation and distribution. Moreover, on-demand production means items are manufactured as needed, decreasing overproduction and the associated waste.

Challenges and Considerations

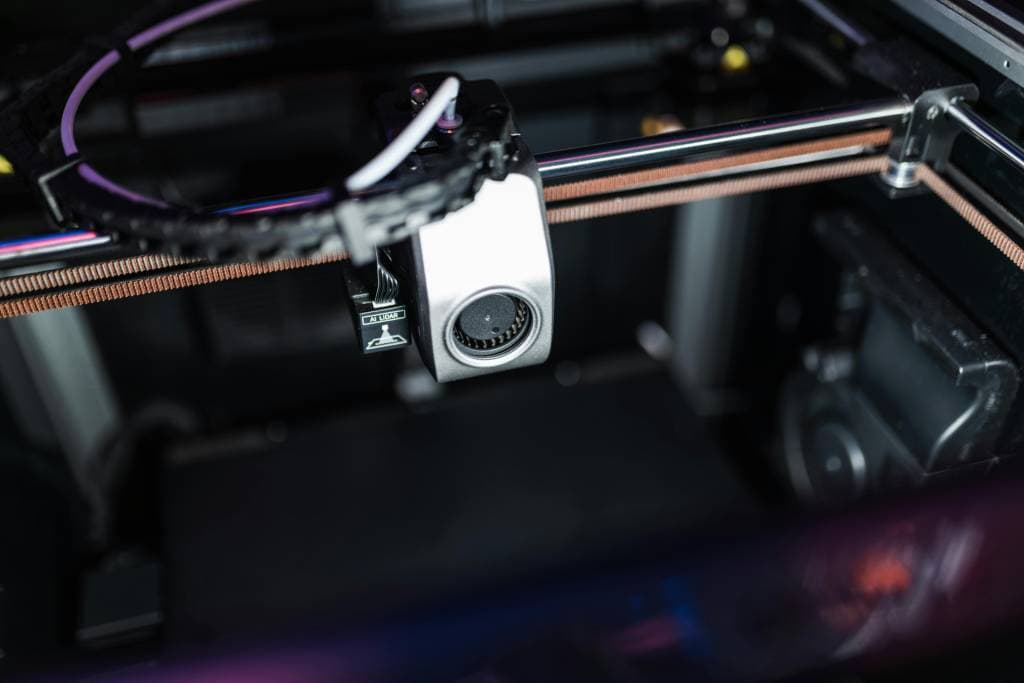

Despite its sustainability advantages, 3D printing presents certain challenges. The energy consumption of some 3D printing processes can be high, particularly those involving metal materials that require high temperatures. Additionally, not all 3D printing materials are recyclable, and the production of certain polymers can have environmental impacts. Ongoing research aims to address these issues by developing more energy-efficient technologies and expanding the range of sustainable materials available for 3D printing.

Innovative Applications Promoting Sustainability

Several recent developments highlight the role of 3D printing in promoting sustainability:

- Recycling Fishing Nets into 3D Printing Materials: A Cornish start-up, Fishy Filaments, recycles discarded fishing nets into engineering-grade nylon suitable for 3D printing. This initiative addresses plastic pollution and provides sustainable materials for manufacturing. The Times & The Sunday Times

- 3D-Printed Housing: In Georgetown, Texas, a robot has created the world’s largest 3D-printed neighborhood, consisting of 100 homes. This method reduces construction waste and utilizes resilient materials, contributing to sustainable housing solutions. The US Sun

Conclusion

3D printing holds significant promise for enhancing sustainability in manufacturing and production. By reducing material waste, enabling energy-efficient designs, and facilitating the use of recycled materials, it contributes to more sustainable production practices. As technology advances and addresses existing challenges, 3D printing is poised to play an increasingly vital role in promoting environmental sustainability across various industries.

1 Comment

Ashton Porter

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.