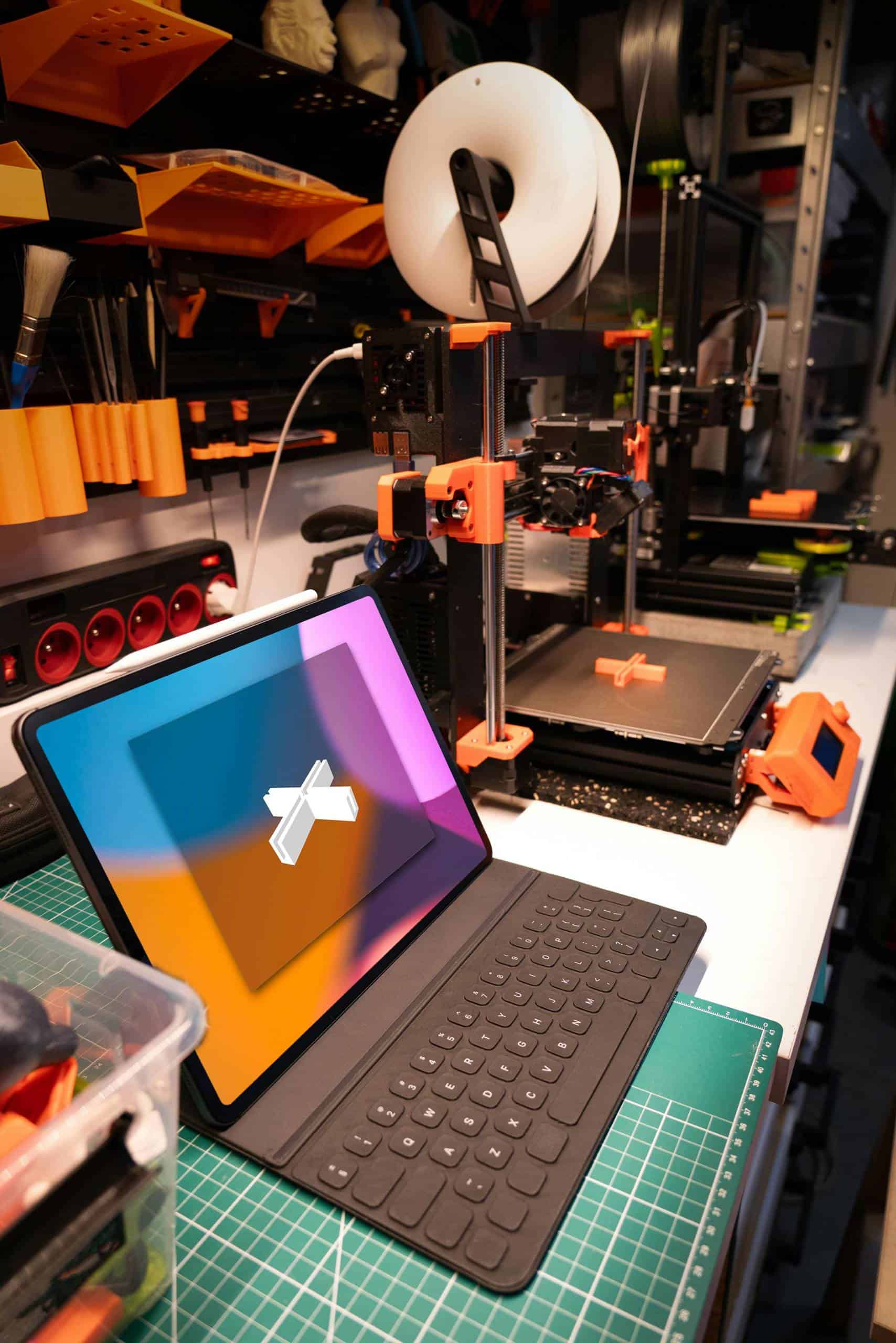

3D printing has transformed prototyping by providing a rapid, flexible, and cost-effective means of bringing ideas to life. As technology continues to advance, its integration with other innovations like AI promises to further streamline and enhance the product development process, enabling designers and engineers to push the boundaries of creativity and functionality.

Advantages of 3D Printing in Prototyping

Speed and Efficiency: Traditional prototyping methods often involve lengthy processes and multiple tools. In contrast, 3D printing streamlines production by fabricating prototypes directly from digital models, significantly reducing lead times. This acceleration facilitates quicker iterations and faster decision-making during product development.

Cost-Effectiveness: By eliminating the need for specialized tooling and molds, 3D printing reduces the expenses associated with prototype fabrication. This affordability allows for the exploration of multiple design iterations without substantial financial investment.

Design Flexibility: 3D printing supports the creation of complex and intricate designs that may be challenging or impossible to achieve with traditional manufacturing methods. This capability enables designers to experiment with innovative structures and functionalities.

Material Versatility: Advancements in 3D printing technologies have expanded the range of materials available, including various plastics, metals, and composites. This diversity allows prototypes to closely mimic the material properties of the final product, enhancing the accuracy of testing and evaluation.

Applications in Various Industries

Automotive: Companies like Audi utilize full-color multi-material 3D printing in automotive design to rapidly produce and test prototypes, expediting the approval process for production.

Consumer Electronics: 3D printing enables the swift development of ergonomic and aesthetically pleasing device prototypes, allowing for rapid user feedback and design adjustments.

Medical Devices: The technology facilitates the creation of customized prosthetics and implants tailored to individual patient anatomies, improving comfort and functionality.

Contact us for all of your prototyping needs! We excel where others falter, and we eagerly embrace challenges. Let us help bring your ideas to life with our innovative solutions and expert craftsmanship. Reach out to us today and let’s create something amazing together!